|

Gravity Conveyors

Got a lot of heavy product that needs to get moved quickly? Our roller- and wheel-bed gravity conveyors make it easier than ever before. A series of rollers and wheels allow you to easily transport packages and products of nearly any size quickly down the line for further handling. Fully compatible with our gravity flow racks to create smooth and fast product transport across any size warehouse or storage facility.

FEATURES

- Spring-loaded for easy installation

- Several options to mount to rack or floor

- Steel is corrosion resistant

- Light weight aluminum option

|

- Light, Standard, and Heavy-duty options

- Available in custom to-the-inch sizes

- 2 year warranty

|

CONFIGURATIONS

These variations of conveyor work with your space to get you a system that fits your unique specifications. Click the images below for a larger view.

|

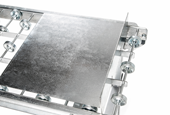

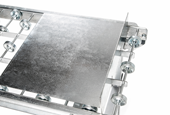

Gravity Conveyor with Gate

|

This configuration allows personnel to cross the conveyor without climbing over or under.

|

|

Gravity Conveyor with Curve

|

With a 50' curved section, you can transport cartons to the next process or around corners. Available in 45° and 90° angles

|

TECH SPECS

To download a complete list of specifications, click here.

|

|

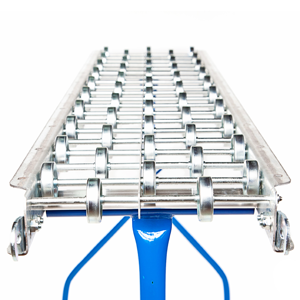

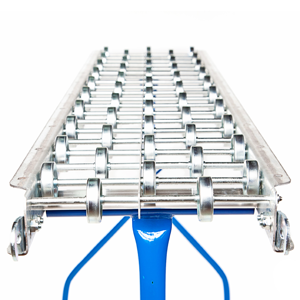

Roller Conveyor

- Available in lengths from 12” to 144” in ½” increments

- 4 standard widths: 12”, 18”, 24”, 30”, 36”

- 3 standard roller centers: 3”, 4 1/2”, 6”

- Steel Construction

- wheel capacity

- 1 3/8” diameter by 18 ga. galvanized steel roller

- C Channel 2.5” by 1” leg by 12 ga. galvanized steel channel frame

- 1 3/8"JRS capacity = /roller and /ft

- 1.9 MRS capacity = /roller and /ft

- Aluminum Construction

- wheel capacity

- 1 3/8” diameter by .065 aluminum roller

- Mounted in a 2.5” high by 1” leg by .112 extruded aluminum channel frame

- 1 3/8"JRS capacity = /roller and /ft

|

Wheel Bed Conveyor

- Available in lengths from 12” to 144” in ½” increments

- 4 standard widths: 12”, 15”, 18”, 24”

- ¼” diameter carbon steel axles, threaded with locknut, spaced on 3” centers

- Steel Construction

- wheel capacity

- 1 15/16” diameter zinc-plated steel wheels

- C-Channel 2.5” high by 1” leg (7/8” for carton flow) by 12 ga. galvanized steel channel frame

- Aluminum Construction

- wheel capacity

- 1 15/16” diameter aluminum wheels

- Mounted in a 2.5” high by 1” leg by .112 extruded aluminum channel frame

|

ACCESSORIES

|

|

|

|

|

|

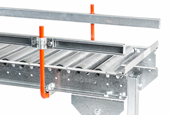

Package Stop

|

Roller Stop

|

Fixed Angle End Stop

|

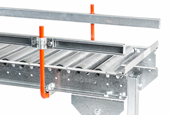

Adjustable Guard Rail

|

Fixed Angle Guard Rail

|

|

Steel protection to handle toughest loading conditions

|

Allows loads to be supported while taking product from the end of the conveyor.

|

Mounts to the end of a conveyor to stop flow. Available in all standard conveyor widths

|

Available for straight or curved sections and one or both sides

|

Can be toed in or out. Available for straight or curved sections and one or both sides

|

VIDEO

CASE STUDY: Capital Candy

UNEX Strings Together a Collection of Carton Flow Solutions

for Candy Wholesaler and the Results are Sweet!

|

In 1938, a Mom & Pop penny-candy operation opened in a small Vermont town. Success followed, and Capital Candy Co., Inc. emerged as a full-fledged wholesaler for grocery and convenience stores. Growth was good, and more was on the way. At a rapid fire pace, manufacturers began introducing new product extensions by the hundreds. Capital Candy was running out of space and the surges in inventory made the need to increase productivity greater than ever.

Read more...

|

|

|